GOOGLE’S TALKING SHOES

Shoes with a personality, interpreting your real-time movement data and telling your story via Google+.

Lead Hardware, Firmware, Mobile App Development.

ROLE

Bluetooth Radios, Inertial Movement Sensors + Data, FSR Sensors, RF Wireless, Audio Amplification, Native Android Application, Social API Integration

TECH

TEAM

ABC News, TechCrunch, AdAge, CNET, Guardian, Business Insider, Fox News, + more…

PRESS

In January 2013, I began working with Zach Lieberman and YesYesNo on the Talking Shoe project from the Art, Copy, Code team at Google. I led all hardware development for the Google Talking Shoe project, including PCB design, embedded sensor integration and firmware for interpreting motion data. There were two iterations of the Talking Shoes; for SXSW and the Cannes Lions festival in 2013 and 2014.

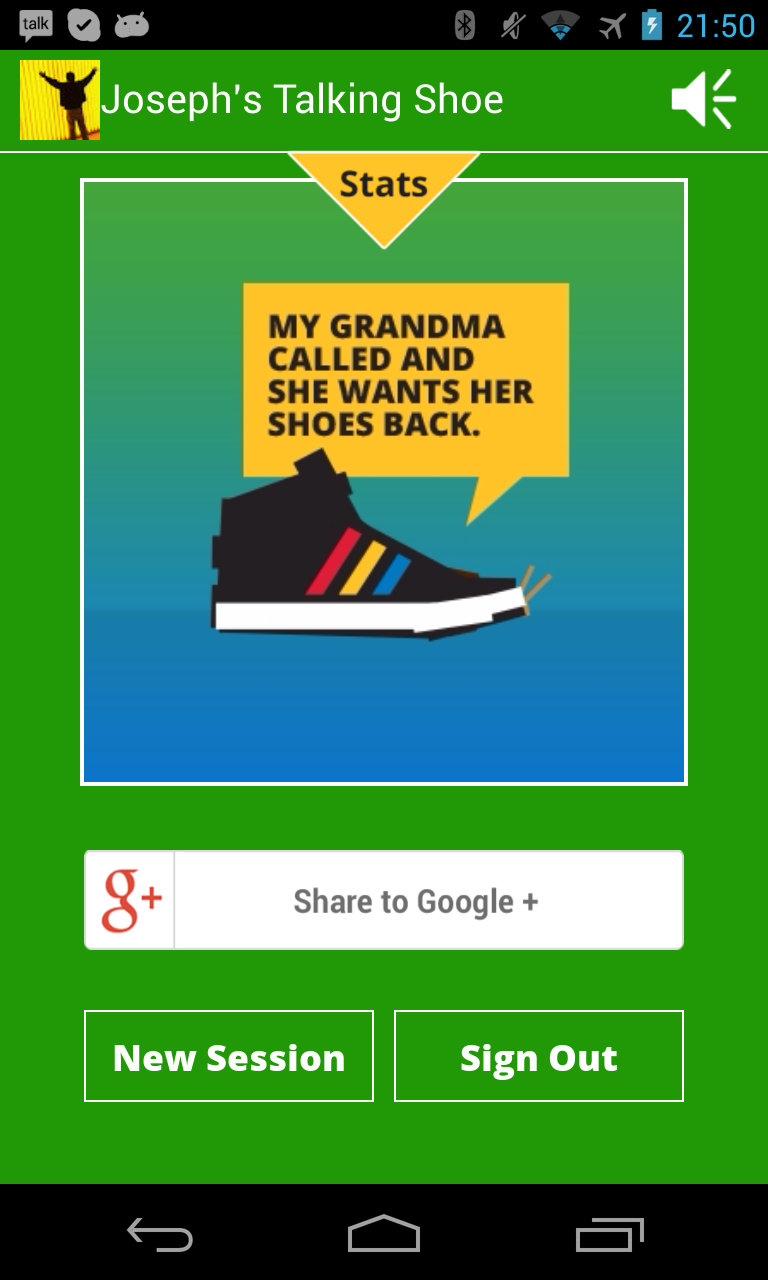

Zach and myself collaborated on the native Android application which would analyze raw sensor data streaming from the shoes to algorithmically identify various movements such as walking, jumping, kicking, sitting, and twirling. When an activity is detected, the shoe provides audio feedback in the form of a voice announcing pithy remarks such as "Try harder" or "My mother can jump higher than you". Upon ending a session, the user is then presented a 'badge' in the form of a GIF which they could post directly to Google+.

The goal of the Art, Copy, Code team at Google was to make a case for how wearable, connected objects can tell stories about our quantified physical lives. The project got almost too much attention, and Google had to issue a press release saying that no, they were not in fact working with Adidas to create a shoe product: this was simply an experiment.

Shoe 2.0: The Communication Board lives in the tongue of the shoe and features the power management (LiPo recharge), a Bluetooth module (bottom side, running a speaker profile for audio throughput), 8 Ω speaker + amplification circuitry, an RF antenna for communicating with the other foot, and a Molex connection to the shoeIMU sensor board embedded in the sole.

The inertial movement Sensor Board I designed lives in the sole of each shoe. It contains a 9-axis IMU sensor, header connections for 3 FSR pressure sensors at the toe, ball, and heel of the sole, and a molex terminal to connect to the CommBoard.